Material Master Data Management

Material Master Data Management: Materials MDM: The Foundation of Your Business

Materials Master Data Management (MDM) serves as the central repository for critical business information, encompassing products, materials, vendors, customers, and more. It’s an essential component of any Enterprise Resource Planning (ERP) system used in distribution or manufacturing.

By consolidating material data into a single, reliable source, MDM eliminates the inefficiencies caused by data redundancy. By effectively managing duplicate records and creating accurate BOMs, materials MDM

Creating Bills of Materials (BOMs) in Materials MDM

BOMs are essential for manufacturing and assembly processes. Materials MDM systems can play a crucial role in BOM creation and management.

⦁ BOM Structure: Define the hierarchical structure of BOMs (e.g., parent-child relationships).

⦁ Component Relationships: Establish relationships between components and their parent assemblies.

⦁ BOM Attributes: Define attributes such as quantity, cost, and lead time for each component.

⦁ BOM Revisions: Manage changes to BOMs over time.

Integration with Other Systems: Integrate BOM data with ERP, PLM, and other relevant systems.systems can significantly improveoperational efficiency and reduce costs.

Material Master

Data Dump from Client

Data Audit

Data

Classification

Data

Cleansing

Data

Enrichment

Codification/Schema Classification

De-Duplication Identification

Data

Standardization

Data

Normalization

Manufacturer/Vendor Validation

Data Uploading & Preparation

Data Dump from Client

Data Audit

Data

Classification

Data

Cleansing

Data

Enrichment

Manufacturer/Vendor Validation

Data Normalization

Data Standardization

De-Duplication Identification

Codification/Schema Classification

Data Uploading & Preparation

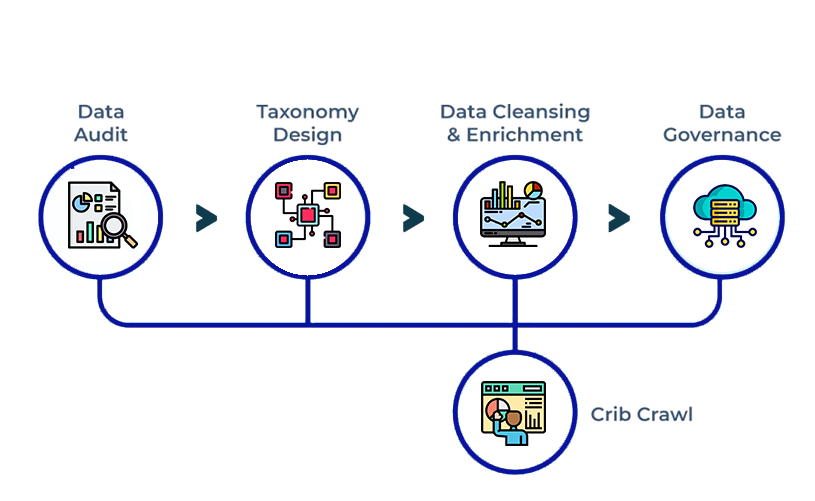

Data Audit

Data Classification

Data Cleansing

Data Enrichment

Data Standardization

Data Normalization

De-Duplication Identification

UNSPSC classification or codification

Data Uploading & Preparation

A Journey to MRO DATA EXCELLENCE

Vendor Master

Data Aggregation

Data Cleansing

Data Collection Primary/

Secondary

Vendor Codification

Parent - Child

Realtionship

Upload to ERP System

Enriched

Identified

Importance of Accurate Material Master Data for ERP/MDM

Data Quality Improvement

Operational Efficiency

Cost Reduction

Regulatory Compliance

Customer Satisfaction

Material data cleansing within an MDM framework is essential for maintaining data quality, improving operational efficiency, reducing costs, ensuring regulatory compliance, and ultimately enhancing customer satisfaction.

1.Data Quality Improvement

⦁ Elimination of Duplicates: MDM helps identify and remove duplicate records, preventing inconsistencies and errors.

⦁ Standardization: Ensures that data is formatted and structured consistently across the organization.

⦁ Accuracy: Helps maintain the accuracy of material information, such as descriptions, specifications, and classifications.

2. Operational Efficiency

⦁ Streamlined Processes: Clean and accurate data enables smoother workflows and reduced errors.

⦁ Improved Decision Making: Reliable data supports informed decisions across various departments.

⦁ Enhanced Supply Chain Management: Accurate material data facilitates efficient procurement, inventory management, and production planning.

3. Cost Reduction

⦁ Reduced Errors: Fewer errors lead to lower costs associated with rework, scrap, and delays.

⦁ Optimized Inventory: Accurate material data enables better inventory management, reducing excess stock and stockouts.

⦁ Improved Supplier Relationships: Consistent and accurate data facilitates better communication with suppliers.

4. Regulatory Compliance

⦁ Data Privacy: Ensures compliance with data privacy regulations like GDPR and CCPA.

⦁ Quality Standards: Helps meet industry-specific quality standards and certifications.

5. Customer Satisfaction

⦁ Accurate Product Information: Clean and accurate material data leads to better product descriptions and customer experiences.

⦁ On-Time Delivery: Reliable data supports efficient order fulfillment and timely delivery.